In the previous post, I mentioned several parallel projects ongoing. This post will focus on the Stepper Motor testing and the issues regarding my pulleys and belts.

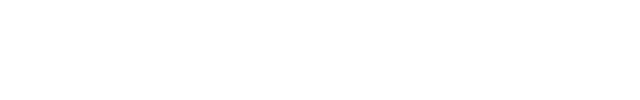

Here’s the current status of the Monster:

The obvious change is the bright yellow belt on the y-direction stepper, and the smaller yellow belt on the x-direction stepper. I ordered those on McMaster Carr and they have a cross-sectional diameter of 3/16″ of an inch. They came with small push-on splices that gave me a small issue, that I’ll address later in this post. The yellow cords are much more slick than I thought, for I was hoping for a belt that had some grip. The one thing that is good about them, is they do not stretch much.

Prior to installing the yellow belts, I decided to verify that my electrical work had functioned as designed. With some simple code testing (to be described in a following post), I was able to get both steppers spinning from two different controllers via one power supply and one USB. In the video below, you can see the sine/cosine action that I coded in my C# testing application.

Well that looked promising.

However, my excitement was short lived. I ran into a bunch of issues with my belts.

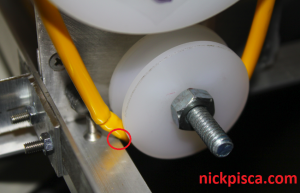

Take for example the Y-Direction belt shown in the image above. The assembly consists of four pulleys. The stepper has a 3″ diameter pulley, the two threaded rods have 1.5″ diameter pulleys, and there is one 3″ diameter tensioner pulley at the middle. Unfortunately, the belt is very slick. The top stepper pulley spins without moving the belt and subsequent pulleys. I remedied this with the use of a tight and wide rubber band, however now the tape bushing I developed to mount the pulley now spins inside the center of the pulley. I need to shim that maybe a 1/64″ or less to secure it. I’m still worried that the stepper will not have enough torque to spin all four pulleys, but when I test them with my hand, they offer almost no resistance. I may need to replace the circular belt to a chain, because there appears to be some sort of friction coming from the walls of the pulley or belt. I’m really surprised the belt is the cause of such resistance.

Next, I ran into a bunch of problems with my X-Direction belt. This should be the easiest system, because it is the simplest pulley-belt assembly, shortest belt, and it’s only working against a small one-rod system. Instead, it’s been trying.

1. I cut the belt too short. I wanted it to be very very very tight, so I cut the belt 1/4″ short and pulled the ends together. The splice simply snaps into the center of the hollow core belt and it fit for about ten seconds. Then it separated due to the tension in the belt.

2. I cut the belt bigger, but it slipped too much. I had to find a happy medium, which allowed the belt to be snug, not separate, and rotate the smaller pulley.

3. I finally got a belt size that worked, but it’s looseness allowed for a clash. After sizing the darn thing, it has a slight bump at the splice around the lower left corner of the assembly, and it grazes the X-direction support tray. I found this out the hard way, because I was coding the test application from the other side of the tray. I couldn’t figure out why it wasn’t spinning smoothly. After slathering the rod and gliders with synthetic grease, it appeared to have no difference in the spin. That’s when I found the clash.

I’ll have to take apart the tray and drill out a small notch for this. Hopefully, it will not require a full disassembly.

I tried lubricating more of the rods and gliders to help fight against the friction, but it doesn’t appear to help. Maybe I need to work this into the threads more before going to primetime. I’m beginning to think that I should have invested some money in a chain system, either plastic or aluminum. Gear driven sounds pretty tight to me. I was hoping belts would be a good fail-safe though, because since my CNC Monster does not have any boundary check mechanisms, if the machine goes haywire and runs off the end of the table, the pulley will just spin inside the belt. If I go down the path for a chain system, that could be really hard on the steppers if it presses up against the side of a rail without any release.

Luckily, my programming is going much more smoothly than the issues with the belts. I’ll go more in depth with that in the next post.

![[0001D] Mega-Dots Automated Name Distribution](https://www.nickpisca.com/sherpa/wp-content/uploads/2015/07/20151112_XMLCTDImporter03.jpg)

Trackbacks/Pingbacks